I. Overview of Machine Tool

This sawing machine is suitable for cutting billets, plates, and bars with a height of ≤ 500mm and a width of ≤700mm. The machine can cut various soft and hard ferrous or non-ferrous metal materials through selecting appropriate parameters and adjusting different speeds, and it is an energy-saving cutting equipment for large and medium-sized enterprises.

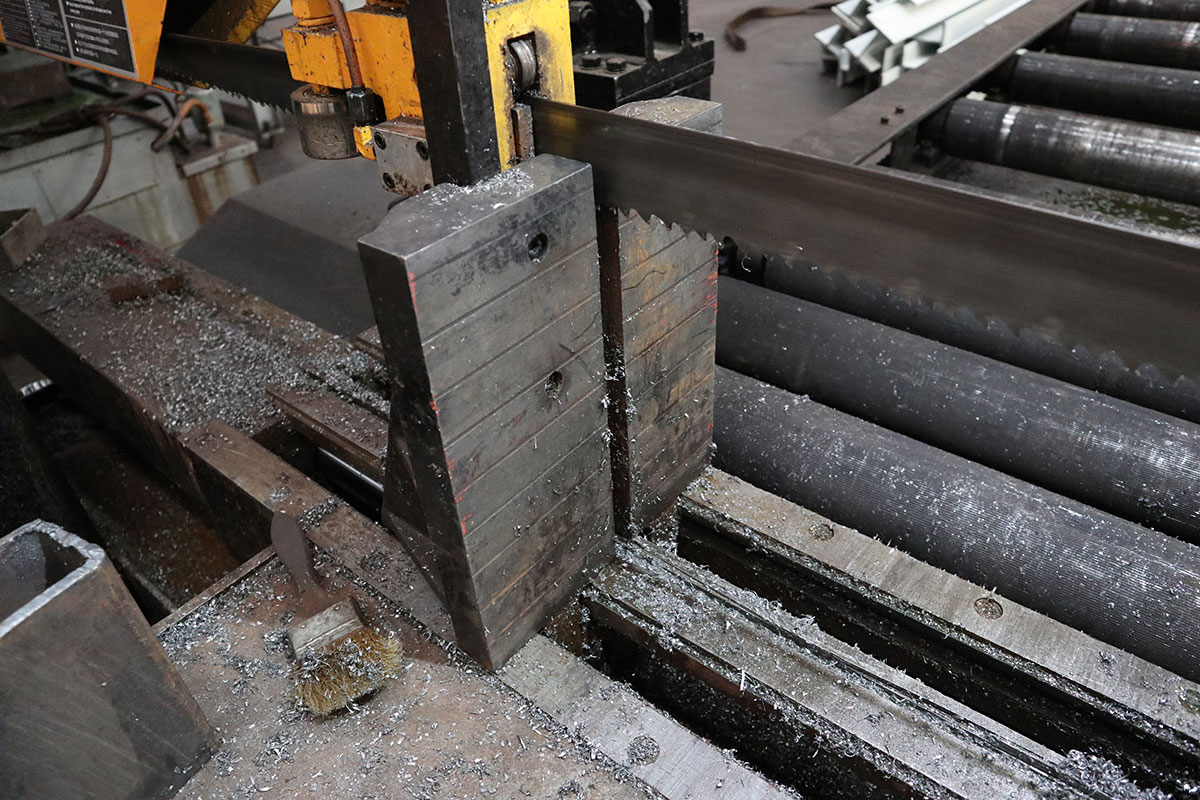

The H-7050 double-column (one is round and the other is square) horizontal band sawing machine is a new generation of band sawing machine designed and developed by the company. The product features with double-column guide, reliable performance and artistic appearance. The surface of the main column is coated with hard chrome providing wear-proof performance and high precision and prolonging the service of the machine tool. With the functions of hydraulic lifting, stepless speed regulation, and self-set range, the good sawing conditions can be easily met. The machine tool adopts the hydraulic clamping device for convenient operation. The saw blade adopts bearings and adjustable tungsten carbide blades to ensure sawing accuracy.

II. Key Technical Parameters

| Sawing capacity(mm) | ○500 □W700×H500 |

| Saw blade specification(mm) | 41×1.3(The length is measured as actual) |

| Cutting speed(m/min) | 20-69 m/min Variable frequency speed regulation |

| Feed speed(mm/min) | Hydraulic stepless speed regulation |

| Machine input power | 380V 50Hz |

| Main motor power(Kw) | 7.5 |

| Hydraulic station motor power(Kw) | 1.5 |

| Pump motor(Kw) | 0.09 |

| Workpiece clamping method | Hydraulic horizontal clamping |

| Machine control voltage | DC 24V |

| Hydraulic system pressure(MPa) | 3.5 |

| Feeding method | Roller cycle automatic feeding |

| Roller length(mm) | 1500 |

| Water tank volume(L) | 80 |

| Hydraulic tank volume(L) | 80 |

| Work bench load(t) | 5 |

| Machine packing size(mm) | 1300×3500×1800 |

| Machine weight(t) | 5 |

III. Structural Features of Machine Tools

Main components and functions of machine tools

1. Base: The base is welded with steel plates that are subject to the vibration aging treatment with less welding formation, and it is primarily used to accommodate all parts of the machine tool.

2. Work bench: The sliding fixed work bench is used, and it is composed of a main work bench, a movable vise and a fixed vise. The movable vise is used to provide the clamping action.

3. Main drive system: The main drive system of the machine tool is composed of a worm gear box, a drive wheel, and a belt pulley. The worm gear box and the main drive wheel are directly connected to ensure smooth transmission without impact. The speed of the saw band can be adjusted by the frequency converter to obtain various speeds.

4. Electric feeding system: A 3m rack is used for electric feeding, and the feeding length is not limited; with the indefinite feeding length, it is suitable for sawing long materials, and the H-7050 mobile support trolley is provided.

5. Saw frame: The steel frame adopts the arched structure, and the saw frame plates adopt steel plates. The saw frame is made of by reasonably welding reinforcement ribs that the welding stress is redistributed and eliminated after vibrating aging to ensure the stability of the saw frame. The drive wheel, driven wheel, and left and right guide devices are all installed on the saw frame, and the saw wheel rotates counterclockwise during the operation of the machine tool.

6. Guiding device: The guide device of this machine tool is divided into movable guide arm and fixed guide arm. The movable guide arm moves automatically with the opening and closing action of the vise, and the guide arm is locked hydraulically and automatically when sawing. The top and sides of the guide seat are made of cemented carbide, and there is also a pre-guide device to ensure the stability of the guide and prolong the service life of the saw blade.

7. Saw band tensioning device: The saw band is tensioned hydraulically. The slider is driven by the hydraulic cylinder to make the driven wheel move in the tensioning seat, so as to tension the saw blade. There is a belt breakage protection device on the saw frame.

8. Column structure: In order to improve the stability of the machine tool, the machine adopts a double column (one is round and the other is square) method, and the lifting action of the saw frame is driven by an oil cylinder.

9. Hydraulic system: The hydraulic system is composed of 1 oil tank, 1 hydraulic motor, 1 oil pump, 1 speed regulating valve, and multiple solenoid valves. The main solenoid valves and hydraulic pumps adopt products from domestic companies.

10. Cooling and chip removal system: In order to prolong the service life of the saw blade, prevent the saw blade from heating up, and ensure the sawing accuracy, the machine tool adopts a cooling pump for centralized cooling. Coolant can be automatically recovered for recycling. There is an automatic chip removal system for convenient and centralized collection and treatment of sawdust.

11. Electrical system: A separate electrical control cabinet is designed in this machine tool, and all electrical components are installed in the electrical cabinet. There is an interlock between the actions. The specific description is as follows: If the vise does not clamp the workpiece firmly, the main drive cannot work; the vise cannot be release in the sawing process; the front vise clamps the workpiece, but materials cannot be fed.

IV. Process and Quality

● A new product that fully meets the standards and has passed the strict inspection

● The main structures (such as machine bed and saw frame) are subject to the surface sandblasting and vibration aging treatment (internal stress removal process) to ensure the elimination of internal stress and improve surface adhesion.

● The German process technology and management technology are adopted for the quality control of the entire process.

● The main drive worm adopts the following processes: blanking → rough machining → quenching and tempering → fine processing → surface quenching → gear teeth grinding processes.

V. Technical Standards

This machine tool complies with the following standards:

JB/T4318.2 - 2013 Horizontal band sawing machine – Testing of the accuracy

GB/T23572-2009 Hydraulic system general specifications for metal cutting machine tools

GB/T5226.1-2008 Electrical safety of machinery – Electrical equipment of machines – Part 1: General requirements

JB16454 – 2008 Sawing machines for metal cutting – Safeguarding specifications

VI. Main Electrical and hydraulic Components

1. Main hydraulic components

| No. | Part name | Part model | Qty. | Supplier |

| 1 | Lifting cylinder | 100x530 | 1 | Boxin Machinery |

| 2 | Clamping cylinder | 80x550 | 1 | Boxin Machinery |

| 3 | Feed electric unit | 1.5kw cycloidal pin gear reducer | 1 | |

| 4 | Solenoid valve | DSG-02-3C2-DL-DC 24V | 4 | Taiwan Northman |

| 5 | Solenoid valve | DSG-02-2B2-DL-DC 24V | 1 | |

| 6 | Three-phase asynchronous motor pump set | YT-90J 1.5kw- 4P | 1 | Shanghai SAN-U |

| VA1-20F-A3 | 1 | |||

| 7 | Speed control valve | FNC-G02 | 1 | Taiwan SANLI |

| 8 | Worm gear box | 1:36 | 1 | Boxin Machinery |

2. Main electrical components

| No. | Part name | Part model | Qty. | Supplier |

| 1 | Control transformer | BK-300VA | 1 | Tengen Electric |

| 2 | Programmable controller | 1 | Siemens | |

| 3 | AC contactor | LC1E-1210 | 2 | Schneider |

| 4 | Inverter | 11kw | 1 | Siemens |

| 5 | Miniature relay | RXM2LB2BD | 9 | Schneider |

| 6 | Thermal relay | LRE16N | 2 | Schneider |

| 7 | Circuit breaker | DZ47-63 C3 | 2 | Tianzheng Electric |

| 8 | Water pump | DB-12A-12L/min | 1 | Taizhou Huafeng |

| 9 | Circuit breaker | DZ47-63 C32 | 1 | Tianzheng Electric |

| 10 | Circuit breaker | DZ47-63 C6 | 1 | Tianzheng Electric |

| 11 | Touch screen | 7‘’ | 1 | Siemens |

| 12 | Main motor | 7.5KW 960r/min | 1 | Shanghai Dedong |

| 13 | Power switch | HZ5D-2014 | 1 | Shanghai Liao Shun electrical appliances |

Home

Home Consult

Consult Products

Products