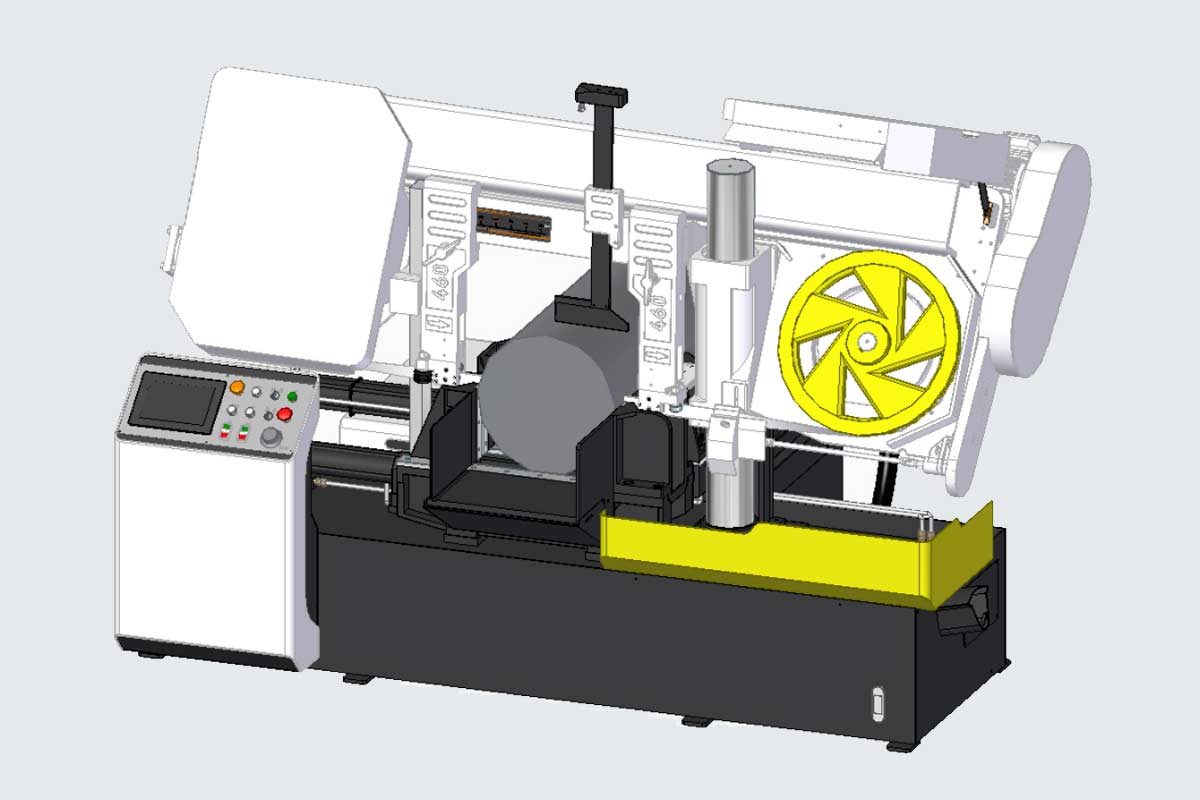

I. Equipment Overview

This machine is a device that adopts the double-column structure for sawing metal materials with a bimetallic band saw blade. It has a PLC programmable electrical control system and an innovative intelligent sawing system that can automatically adjust the sawing parameters such as sawing speed and saw blade liner speed of the selected material. The machine tool can be operated through the PLC display screen, and the switching between the auto control and the manual control can be realized through the display screen. The workpiece is fed through the hydraulic cylinder of the machine, and the high-precision magnetic grating ruler is used for positioning, providing advantages of high feeding accuracy.

The product has the advantages of compact structure, artistic appearance, fast sawing speed, high precision, narrow sawing gap, and low noise, and it is a new energy-saving product instead of circular saws and hacksaw machine, which is widely suitable for cutting various ferrous and non-ferrous metal materials in many industries such as electromechanical, metallurgical, automotive, bridge, and ships, especially for automatic sawing of long materials.

II. Main Technical Parameters

| Sawing range | Round stock φ460mm Square stock 460×460mm |

| Saw blade specification | 41×1.1×5650mm |

| Main motor power | 7.5kw |

| Saw blade linear speed | 15~100m/min(Variable frequency speed regulation) |

| Feed speed | Hydraulically adjustable |

| Hydraulic motor power | 1.5kW |

| Cooling pump power | 0.09kW |

| Saw band cooling method | Emulsion circulation cooling |

| Workpiece clamping method | Hydraulic horizontal clamping |

| Saw band tensioning method | Hydraulic tensioning |

| Hydraulic tank volume | 55L |

| Water tank volume | 120L |

| Chip removal mode | Automatic chip removal |

| Repeated feeding accuracy | ±0.15mm |

| Feeding stroke | 0~500mm |

| Work bench load | 1t |

| Supply voltage | 380V 50Hz |

| Machine control voltage | 24V DC |

| Power voltage Saw section verticality | .2/100mm |

| Outline dimensions of machine | 2850(W)×2300(L)×1700(H)mm |

| Machine weight | 2900kg |

III. Components and Function Description of Machine Tool

According to the function of each part, the machine tool is divided into the following parts: main transmission part, saw band tensioning mechanism, clamping mechanism, saw frame, feeding and sizing mechanism, cooling system, hydraulic system, lubrication system, and electrical system.

1. Main transmission part: The main transmission system of this machine tool adopts a worm gear reducer equipped with a variable frequency motor, featuring with stable output torque and low noise. Many linear speeds of the band saw blade can be obtained through the frequency converter regulation.

2. Saw band tensioning mechanism: The saw band is tensioned through the hydraulic system, and the operation switches are integrated on the operation panel for convenient operation. By moving the driven wheel in the tensioning seat through the hydraulic cylinder, the saw blade is then tensioned. There is a broken band protection device on the saw frame to stop the equipment automatically in the event of a broken or blocked saw blade.

3. Clamping mechanism: The workpiece clamping part is divided into two parts: front clamp clamping and feeding clamping. The front vise adopts a short head with a middle unloading structure, and such short head is more than half shorter than e head of ordinary CNC sawing machines. The workpiece is clamped horizontally by a hydraulic cylinder, and there is a micro cylinder on the feeding fix vise side, and it will open when the feeding work bench is moving under no load to ensure no contact between the vise and the workpiece, so that the feeding accuracy is improved. There is an upper clamping device, which not only prevents the workpiece from moving up during clamping, but also realizes that multiple materials are sawed easily simultaneously.

4. Saw frame: The steel frame is of the arched structure that is divided into left and right saw frame boxes and beams. The saw frame is made of by reasonably welding reinforcement ribs that the welding stress is redistributed and eliminated after vibrating aging to ensure the stability of the saw frame. The drive wheel, tensioning wheel, and left and right guide devices are all installed on the saw frame, and the saw wheel rotates counterclockwise during the operation of the machine tool.

5. Guide device: The guide device of this machine tool is divided into a movable guide arm and a fixed guide arm. The former can be adjusted manually. The top and side of the guide seat are made of cemented carbide. In addition, there is a pre-guide device to ensure the stability of the guide and extend the service life of the saw blade. There is a fast conversion device on the guide dovetail, improving work efficiency thanks to its function of automatic fast feed conversion to workpiece feed.

6. Feeding and sizing mechanism: This mechanism is an automatic feeding device, which can realize automatic feeding of the machine tool. The feeding vise is hydraulically clamped, and the feeding vise is driven by a hydraulic cylinder. The single feeding stroke is 500mm. The feeding length is determined by a high-precision grating ruler, and it can be set directly on the panel for convenient operation. there is a no-material detection on the feeding vise to realize the automatic shutdown when there is no material.

7. Cooling and chip removal system: In order to improve the service life and sawing accuracy of the saw blade, the cooling system is designed in this machine tool, and cooling points are provided at two guide positions. The coolant is automatically recovered for recycling use. A power chip removal wheel is provided behind the right guide head of the machine tool, which can timely discharge the sawdust stuck on the saw teeth, ensuring the stability of sawing process and the service life of the saw blade. There is an automatic chip removal system, which can discharge the sawdust timely for centralized treatment.

8. Hydraulic system: There is an independent hydraulic station designed in this machine tool to realize the hydraulic action of the machine tool and the entire production line. All valve components are installed on the integrated block, and the action of each solenoid valve is controlled by the electrical system to realize the operation of the machine tool and the production line. The hydraulic station is primarily composed of an oil tank, a hydraulic motor, an oil pump, a speed regulating valve, a relief valve, and a solenoid valve.

9. Lubrication system: In order to ensure the normal operation of the machine tool, the corresponding parts of the machine tool shall be filled with lubricating oil regularly. The main lubricating parts and lubrication cycles are as follows:

Worm gear box: Lubricated with gear oil, it is replaced once a year;

Guide column: Lubricated with guide rail oil; with automatic control; check the oil level in the lubricating oil tank every shift, and add the oil timely.

Feeding slide rail: Lubricated with guide rail oil; with automatic control; check the oil level in the lubricating oil tank every shift, and add the oil timely.

10. Electrical system: The machine tool adopts a separate control cabinet, all operations are performed by touch screen, and the PLC programmable controller is used to control each action. The new intelligent sawing system is used, with built-in sawing parameters of multiple materials. Users can also customize and save material parameters. The system can automatically adjust the sawing parameters of the selected materials such as sawing speed and saw blade linear speed; the sawing speed can be adjusted automatically in the sawing process, thus effectively improving the sawing efficiency (increased to 150% the efficiency of general CNC sawing machines). There are Manual and Auto models for electrical operations. The Manual mode is primarily used for machine adjustment and sawing operations of the head and tail of the material. After the head of the material is sawed, it will switch to the Auto mode, which can realize single-cycle automatic sawing of the bar material. With the no-material detection function, the machine automatically stops when there is no material. There is an interlock between each electrical action. According to electrical safety standards, all electrical components are installed in the electrical cabinet. The electrical cabinet has the function of power outage when the door opens, and the components in the control box all adopt 24V DC. The product obtains the 3C certification for complete sets of low-voltage appliances, and the electrical equipment complies with the national and international standards. The machine tool has overload protection and belt break safety protection devices.

IV. Technical Standards

The machine tool complies with the following standards:

JB/T4318.2 – 2013 Horizontal band sawing machine – Testing of the accuracy

GB/T23572-2009 Hydraulic System General Specifications for Metal Cutting Machine Tools

GB/T5226.1-2008 Electrical safety of machinery – Electrical equipment of machines – Part 1: General requirements

JB16454 – 2008 Sawing machines for metal cutting – Safeguarding specifications

V. Key Hydraulic and Electrical Components

1. Key hydraulic components

| No. | Part name | Part model | Qty. | Supplier |

| 1 | Lifting cylinder | Ø90x490 | 1 | Boxin Machinery |

| 2 | Clamping cylinder | Ø70x 480 | 1 | Boxin Machinery |

| Ø80x 480 | ||||

| 3 | Feeding cylinder | Ø63x500 | 1 | Boxin Machinery |

| 4 | Solenoid valve | 02-3C2-DC 24V | 5 | Northman |

| 5 | Solenoid valve | 02-2B2-DC 24V | 1 | |

| 6 | Oil pump motor set | 1.5kw | 1 | SAN-U |

| VA1-20F-A3 | 1 | Taiwan Xinhong | ||

| 7 | Speed control valve | G02 | 1 | Northman |

| 8 | Worm gear box | G4243 | 1 | Boxin Machinery |

2. Key electrical components

| No. | Part name | Part model | Qty. | Supplier |

| 1 | Control transformer | BK-300VA | 1 | Tengen Electric |

| 2 | Programmable controller | XD5-48T-E | 1 | Xinjie |

| 3 | AC contactor | CJX2-1210 | 2 | Chint Electric |

| 4 | Inverter | 7.5kw | 1 | Gtake |

| 5 | Miniature relay | JZX-22F(D)/2Z | Chint Electric | |

| 6 | Thermal relay | JR1-09-10A | 1 | Chint Electric |

| 7 | Thermal relay | JR1-09-5A | 1 | Chint Electric |

| 8 | Circuit breaker | DZ47-63 C3 | 1 | Tengen Electric |

| 9 | Circuit breaker | DZ47-63 C20 | 1 | Tengen Electric |

| 10 | Circuit breaker | DZ47-63 C6 | 1 | Tengen Electric |

| 11 | Touch screen | TGA63-MT 10“ | 1 | Xinjie |

| 12 | Stepper motor | 850 | 1 | Taiwan Wage |

| 13 | Grating ruler | WT-0600 | 1 | Guangdong Wanhao |

| 14 | Main motor | YE2-132M-4 | 1 | Shanghai Dedong |

VI. Equipment Diagram

Home

Home Consult

Consult Products

Products