Band saw blade pitch selection and recommendation 1

1. Selection of cutting width and tooth pitch:

The size of the pitch is selected according to the effective sawing width (thickness) of the material.

Reference table for pitch selection - Saw core material

| Equal tooth distribution | Variable tooth distribution | |||||||||

| Pitch of teeth | Contact arc length | Pitch of teeth | Contact arc length | |||||||

| 24 | tpi | to | 6 | mm | 10-14 | tpi | to | 30 | mm | |

| 18 | tpi | to | 10 | mm | 8-12 | tpi | 20- | 50 | mm | |

| 14 | tpi | to | 15 | mm | 6-10 | tpi | 25- | 60 | mm | |

| 10 | tpi | 15- | 30 | mm | 5-8 | tpi | 35- | 80 | mm | |

| 8 | tpi | 30- | 50 | mm | 4-6 | tpi | 50- | 100 | mm | |

| 6 | tpi | 50- | 80 | mm | 4-5 | tpi | 70- | 120 | mm | |

| 4 | tpi | 80- | 120 | mm | 3-4 | tpi | 80- | 150 | mm | |

| 3 | tpi | 120- | 200 | mm | 2-3 | tpi | 120- | 350 | mm | |

| 2 | tpi | 200- | 400 | mm | 1.4-2 | tpi | 250- | 600 | mm | |

| 1.25 | tpi | 300- | 800 | mm | 0.75-1.25 | tpi | 500- | 1200 | mm | |

| 0.75 | tpi | 700- | 3000 | mm | 0.75-1.0 | tpi | 1000- | 3000 | mm | |

Reference table for pitch selection - Sawing pipe profiles

| Wall thickness | Tooth distribution(tpi) Outside diameter of pipe [ mm ] | |||||

| [mm] | 20 | 40 | 60 | 80 | 100 | 120 |

| 2 | 14 | 14 | 14 | 14 | 14 | 14 |

| 3 | 14 | 14 | 10-14 | 10-14 | 10-14 | 10-14 |

| 4 | 14 | 14 | 10-14 | 10-14 | 8-12 | 8-12 |

| 5 | 14 | 10-14 | 10-14 | 10-14 | 8-12 | 8-12 |

| 6 | 14 | 10-14 | 10-14 | 8-12 | 8-12 | 8-12 |

| 8 | 14 | 10-14 | 8-12 | 8-12 | 8-12 | 6-10 |

| 10 | 8-12 | 6-10 | 6-10 | 6-10 | 5-8 | |

| 12 | 8-12 | 6-10 | 6-10 | 5-8 | 5-8 | |

| 15 | 8-12 | 6-10 | 5-8 | 5-8 | 4-6 | |

| 20 | 6-10 | 5-8 | 4-6 | 4-6 | ||

| 30 | 4-6 | 4-6 | 4-6 | |||

| 50 | 3-4 | |||||

| 75 | ||||||

| 100 | ||||||

| 150 | ||||||

| 200 | ||||||

| 250 | ||||||

| 300 | ||||||

| Wall thickness | Tooth distribution(tpi) Outside diameter of pipe [ mm ] | |||||

| [mm] | 150 | 200 | 300 | 400 | 500 | 600 |

| 2 | 10-14 | 10-14 | 8-12 | 8-12 | 6-10 | 6-10 |

| 3 | 8-12 | 8-12 | 6-10 | 6-10 | 5-8 | 5-8 |

| 4 | 8-12 | 8-12 | 5-8 | 5-8 | 4-6 | 4-6 |

| 5 | 8-12 | 6-10 | 5-8 | 5-8 | 4-6 | 4-6 |

| 6 | 8-12 | 5-8 | 5-8 | 4-6 | 4-6 | 4-6 |

| 8 | 6-10 | 5-8 | 4-6 | 4-6 | 4-6 | 3-4 |

| 10 | 5-8 | 4-6 | 4-6 | 4-6 | 3-4 | 3-4 |

| 12 | 4-6 | 4-6 | 4-6 | 3-4 | 3-4 | 3-4 |

| 15 | 4-6 | 4-6 | 3-4 | 3-4 | 3-4 | 2-3 |

| 20 | 4-6 | 3-4 | 3-4 | 3-4 | 2-3 | 2-3 |

| 30 | 3-4 | 3-4 | 3-4 | 2-3 | 2-3 | 2-3 |

| 50 | 3-4 | 3-4 | 2-3 | 2-3 | 2-3 | 2-3 |

| 75 | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| 100 | 2-3 | 2-3 | 1.4-2 | 1.4-2 | ||

| 150 | 2-3 | 1.4-2 | 1.4-2 | |||

| 200 | 1.4-2 | 1.4-2 | ||||

| 250 | 1.4-2 | |||||

| 300 | ||||||

| Wall thickness | Tooth distribution(tpi) Outside diameter of pipe [ mm ] | |||||

| [mm] | 700 | 800 | 900 | 1000 | 1200 | |

| 2 | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 | |

| 3 | 5-8 | 4-6 | 4-6 | 4-6 | 4-6 | |

| 4 | 4-6 | 4-6 | 4-6 | 4-6 | 3-4 | |

| 5 | 4-6 | 4-6 | 3-4 | 3-4 | 3-4 | |

| 6 | 3-4 | 3-4 | 3-4 | 3-4 | 3-4 | |

| 8 | 3-4 | 3-4 | 3-4 | 2-3 | 2-3 | |

| 10 | 3-4 | 3-4 | 2-3 | 2-3 | 2-3 | |

| 12 | 3-4 | 2-3 | 2-3 | 2-3 | 2-3 | |

| 15 | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| 20 | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| 30 | 2-3 | 2-3 | 2-3 | 2-3 | 1.4-2 | |

| 50 | 2-3 | 2-3 | 1.4-2 | 1.4-2 | 1.4-2 | |

| 75 | 1.4-2 | 1.4-2 | 1.4-2 | 1.4-2 | 1.4-2 | |

| 100 | 1.4-2 | 1.4-2 | 1.4-2 | 1.4-2 | 0.75-1.25 | |

| 150 | 1.4-2 | 1.4-2 | 1.4-2 | 0.75-1.25 | 0.75-1.25 | |

| 200 | 1.4-2 | 1.4-2 | 0.75-1.25 | 0.75-1.25 | 0.75-1.25 | |

| 250 | 1.4-2 | 0.75-1.25 | 0.75-1.25 | 0.75-1.25 | 0.75-1.25 | |

| 300 | 1.4-2 | 0.75-1.25 | 0.75-1.25 | 0.75-1.25 | 0.75-1.25 | |

Note: When the beam sawing, the thickness of the workpiece *2 is compared with this table.

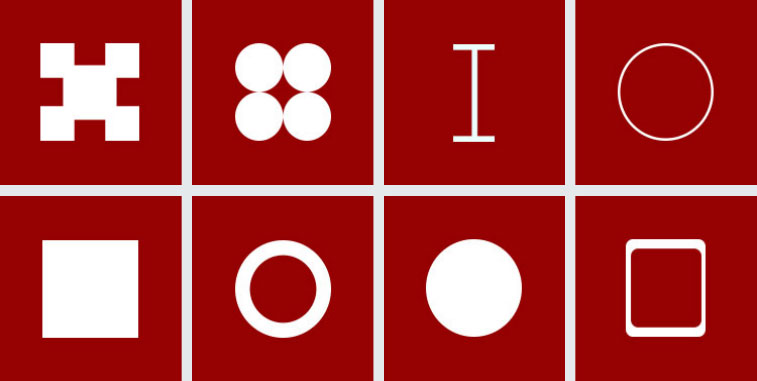

Figure 1

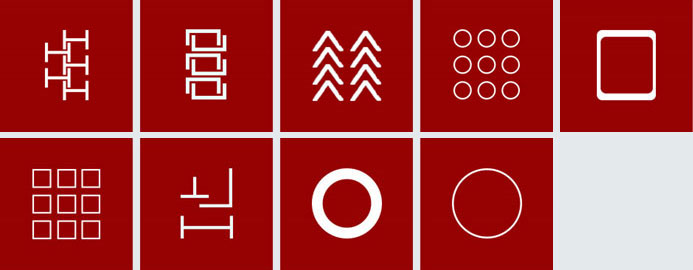

Figure 2

Your location:

Your location:

Home

Home Consult

Consult Products

Products